JOGGING

CUTTING

AUTOMATION

MINIATUREFOLDING

DIE-CUTTING

SADDLESTITCHING

FOLDING

AUTOMATION

DIGITALIZATION

COLLATING

GLUING

CUTTING

We unlock the potential of your business with the power of our connection

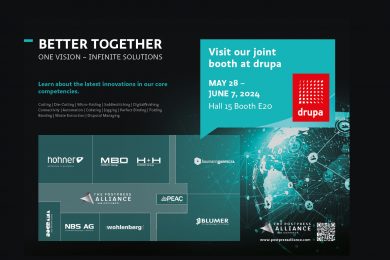

Welcome to the Postpress Alliance, the alliance of leading mechanical engineering companies in the print finishing industry! Established in 2019 from the vision of bringing together the best minds and technologies in the graphic arts industry, the Postpress Alliance unites six traditional brands, each with a unique expertise in its area of competence. From jogging, cutting, die-cutting, folding, to pharmaceutical folding/outsert, wire stitching to perfect binding – you will find the solution perfectly tailored to your needs. With a focus on forward-looking, innovative technologies and automation, we offer you a wide range of high-quality machines including the possibility to optimize your production environment through connectivity. Don’t miss the potential for added value in your production and learn about the difference between a supplier and a partner.

Our partners

Together

we create

future

Together, the Postpress Alliance pushes the boundaries of print post-processing and presents an impressive range of solutions based on the latest technology and covering all aspects of the industry.

JOGGING

CUTTING

AUTOMATING

Innovation Innovative technology instead of man power. The BASA evolution is the latest ...

DIE-CUTTING

Automatic Playing Card Production BOGRAMA specifically implements requirements and even takes them a step ...

MINIATURE

FOLDING

Miniature folds As a manufacturer of customised solutions, H+H positions itself as a competent ...

SADDLESTITCHING

COLLATING

TRIMMING

Spirit of Innovation The needs of our customers are at the center of our ...

FOLDING

AUTOMATION

DIGITALISATION

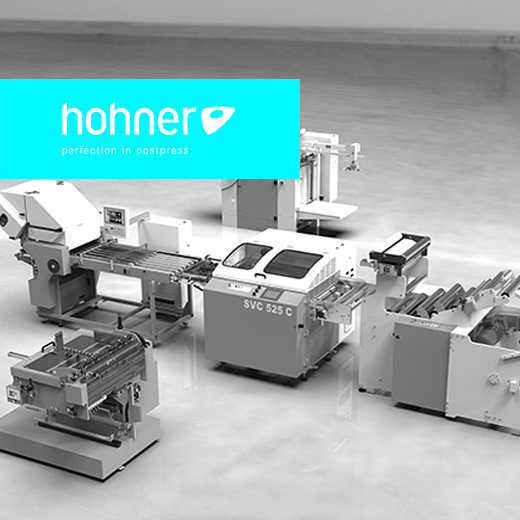

Highend- Folding machines There are many good reasons to choose a folding machine from ...

GATHERING

BINDING

TRIMMING

Gathering machines The Sprinter gathering machines are designed based on the modular concept. All ...

Alliance

NEWS

Get exciting insights and current perspectives in our news blog, presented by the Postpress Alliance.

Latest News 1. November 2023

The Alliance Days 2022: New Machinery at Year’s End

Read MoreWE FOCUS ON

Connectivity/IoT

01

KP-Connect

Is a pressure control software that provides real-time information for task management in production. With integrated control and monitoring, you maintain an overview of production, quality, and service.

02

MIS

Optimize your business organization with MultiPress, the leading MIS software from Dataline Solutions. From estimation to financial control, it provides all the tools you need for top-tier performance in the printing sector.

03

Prepress Workflow

Aepos is an integrated PDF workflow and job management system that enables simple and efficient control of your processes. It automates workflows, minimizes errors, and maximizes the productivity of your machines.

04

Datamanager

With Datamanager 4.0, your production becomes transparent and efficient. Through minute-accurate scheduling, real-time updates, and remote maintenance features, you optimize the finishing process, reduce downtime, and improve the quality of your production.

We bring visions to life with these companies

Feedback to baumannperfecta

Baumannperfecta’s automation solutions have significantly enhanced our operations. The labor-intensive jogging process, once a bottleneck in post-processing, is obsolete with the BASA evolution. We efficiently utilize the BASA both offline and inline, streamlining our procedures.

Axel Schucht

Walcher-Geschäftsführer

Feedback to Hohner

This company excels in innovative mechanical engineering, practical solutions, and networking with module manufacturers. We were impressed by the interesting technology, high reliability, and efficiency of their Hohner collators or digital processing lines.

Ulrich Stetter

Druckhaus Mainfranken GmbH | Managing Director

Feedback to BOGRAMA

For 30 years, we’ve been clients of Bograma, known for innovation, reliability, and quality. A highlight is our rotary die cutter, enabling us to quickly and efficiently produce exceptional, high-quality products.

Norbert Estermann

Founder of Estermann GmbH, Aurolzmünster

Feedback to Hohner

Our establishment of a new company foundation in the USA demanded a partner capable of keeping pace with our dynamic needs. Hohner proved to be the perfect match!